COAXIAL CABLES

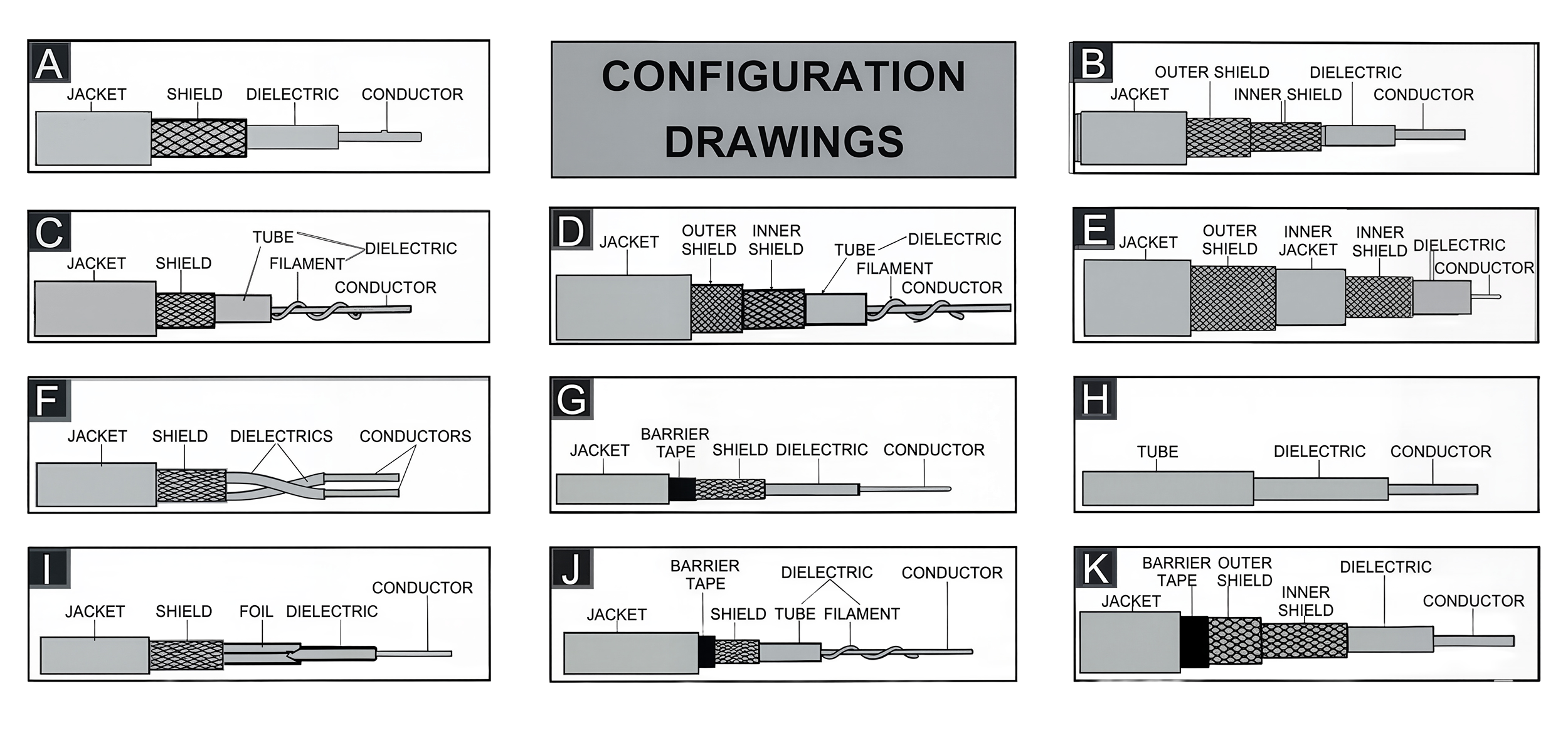

DESCRIPTION: COAXIAL CABLES ARE DESIGNED FOR TRANSMISSION OF HIGH FREQUENCY SIGNALS WITH A MINIMUM OF LOSS. THEY ARE SUPPLIED WITH VARIOUS CONFIGURATIONS, AND THE MOST POPULAR ONES ARE LISTED BELOW. PURCHASING CONSIDERATIONS SHOULD INCLUDE IMPEDANCE, ENVIRONMENTAL TEMPERATURE, WORKING VOLTAGE, SIGNAL LOSS AT SPECIFIC FREQUENCIES, POWER RATING, AND COST. ADDITIONAL INFORMATION ON THESE FACTORS IS AVAILABLE ON REQUEST. PLEASE REFER QUESTIONS ABOUT COAXIAL CABLES NOT LISTED TO OUR SALES DEPARTMENT.

About Coaxial Cables

Jaguar Industries' Coaxial Cables represent premium solutions for high-frequency signal transmission applications requiring minimal signal loss and maximum performance. Engineered for superior electromagnetic interference (EMI) shielding and controlled impedance, our comprehensive coaxial cable line serves diverse markets including telecommunications, broadcast, military/aerospace, medical equipment, test and measurement instrumentation, and data communications. The coaxial cable design, featuring a center conductor surrounded by a dielectric insulator and outer shield, provides exceptional noise immunity and signal integrity for RF and microwave applications.

When selecting coaxial cables, critical factors include characteristic impedance (typically 50Ω or 75Ω), environmental temperature rating, working voltage, signal attenuation at specific frequencies, power handling capability, and cost considerations. Our product line offers extensive material options including conductor types (copper covered steel, nickel/silver plated variations, bare/tinned copper), dielectric materials (polyethylene, PTFE, FEP, PFA, cross-linked polyolefin), and jacket materials (PVC, PVCN, FEP, with fiberglass braid options) to optimize performance for your specific application requirements.

The configuration drawings (A through K) illustrate our range of construction options, from basic single-shield designs to advanced triaxial and specialty constructions featuring multiple shields, barrier tapes, tube filaments, and dual jackets. Each configuration offers distinct advantages: Configuration A provides standard coaxial construction, Configuration B offers dual-shield design for enhanced isolation, Configuration C includes tube filament support, while more complex configurations (D, E, K) deliver superior shielding effectiveness for demanding applications. Our technical sales team can provide detailed specification sheets and application guidance to help you select the optimal coaxial cable construction, ensuring your system achieves the required electrical performance, environmental durability, and cost targets. Contact our sales department for custom configurations and technical support on specialized coaxial cable requirements.