TINNED COPPER TUBULAR BRAID

| CATALOG NO. |

NOM. I.D. (inches) |

NOM. I.D. (mm) |

AWG IND. STRAND |

NO. OF CARRIERS |

TOTAL STRANDS |

NOM. CMA |

APPROX. AWG |

|---|---|---|---|---|---|---|---|

| JTTB-160 | 1/32 (.031) | 0.79 | 36 | 24 | 24 | 600 | 22 |

| JTTB-162 | 1/16 (.062) | 1.59 | 36 | 24 | 48 | 1200 | 19 |

| JTTB-163 | 5/64 (.078) | 1.98 | 36 | 24 | 72 | 1800 | 18 |

| JTTB-164 | 7/64 (.109) | 2.78 | 36 | 24 | 96 | 2400 | 16 |

| JTTB-166 | 1/8 (.125) | 3.18 | 36 | 24 | 120 | 3000 | 15 |

| JTTB-167 | 5/32 (.156) | 3.97 | 36 | 24 | 240 | 6000 | 13 |

| JTTB-168 | 11/64 (.172) | 4.37 | 36 | 24 | 168 | 4200 | 14 |

| JTTB-170 | 13/64 (.203) | 5.16 | 34 | 24 | 192 | 7630 | 11 |

| JTTB-170/1 | 13/64 (.203) | 5.16 | 36 | 24 | 312 | 7800 | 11 |

| JTTB-171 | 1/4 (.250) | 6.35 | 36 | 24 | 384 | 9600 | 10 |

| JTTB-171/1 | 9/32 (.281) | 7.14 | 30 | 24 | 120 | 12060 | 9 |

| JTTB-171/2 | 3/8 (.375) | 9.53 | 30 | 24 | 168 | 16800 | 8 |

| JTTB-172 | 3/8 (.375) | 9.53 | 36 | 48 | 384 | 9600 | 10 |

| JTTB-173 | 7/16 (.438) | 11.11 | 30 | 24 | 240 | 24120 | 6 |

| JTTB-173/1 | 1/2 (.500) | 12.70 | 30 | 24 | 360 | 36000 | 5 |

| JTTB-174 | 1/2 (.500) | 12.70 | 36 | 48 | 528 | 13200 | 9 |

| JTTB-175 | 9/16 (.563) | 14.29 | 30 | 48 | 480 | 48240 | 3 |

| JTTB-175/1 | 21/32 (.656) | 16.67 | 30 | 48 | 768 | 77180 | 1 |

| JTTB-176 | 25/32 (.781) | 19.84 | 36 | 48 | 864 | 21600 | 7 |

| JTTB-177 | 7/8 (.875) | 22.23 | 30 | 48 | 336 | 33700 | 5 |

| JTTB-178 | 1 (1.00) | 25.40 | 30 | 48 | 384 | 38600 | 4 |

| JTTB-179 | 1-1/8 (1.13) | 28.58 | 30 | 48 | 432 | 43300 | 4 |

| JTTB-180 | 1-1/4 (1.25) | 31.75 | 30 | 48 | 480 | 48150 | 3 |

| JTTB-181 | 1-3/8 (1.38) | 34.93 | 30 | 48 | 528 | 53000 | 3 |

| JTTB-182 | 1-1/2 (1.50) | 38.10 | 30 | 48 | 576 | 57775 | 2 |

| JTTB-183 | 1-7/8 (1.88) | 47.63 | 30 | 48 | 672 | 67200 | 2 |

| JTTB-184 | 2-1/4 (2.25) | 57.15 | 30 | 48 | 768 | 77180 | 1 |

About Tinned Copper Tubular Braid

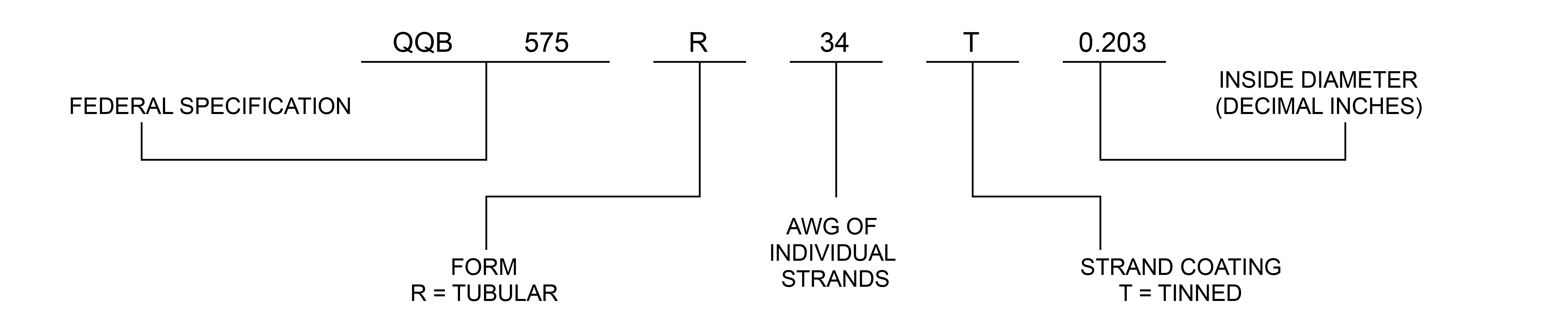

Jaguar Industries' Tinned Copper Tubular Braid offers premium EMI/RFI shielding and grounding solutions manufactured from tinned copper meeting QQ-W-343E and ASTM-B-33 specifications. Conforming to MIL-SPEC QQB-575, our tubular braids are engineered to provide 90% minimum coverage when placed over a mandrel representing the nominal I.D. of the product (70% minimum for .078" and smaller I.D.), ensuring optimal electromagnetic shielding performance. Available in a comprehensive range of inside diameters from 1/32" (0.031") to 2-1/4" (2.25"), with various AWG individual strand sizes (30, 34, and 36), carrier configurations (24 or 48 carriers), and total strand counts. Each specification includes detailed nominal CMA (Circular Mil Area) and approximate AWG equivalent ratings for precise electrical design requirements. Our tinned copper tubular braids provide excellent flexibility, electrical conductivity, and corrosion resistance for cable shielding, grounding straps, EMI shielding assemblies, and electrical bonding applications in aerospace, military, industrial, and commercial electronics. Silver plated and bare copper options also available upon request.